In the quest for sustainable energy solutions, biofuels have emerged as a promising alternative to traditional fossil fuels. Among the diverse array of biofuel options, wood chips stand out for their versatility and accessibility. Producing your own wood chips for biofuel not only offers environmental benefits but also empowers individuals and communities to take control of their energy future. Let’s explore this fascinating avenue in-depth, assuming a reader well-versed in biofuel concepts but keen on practical implementation and optimisation.

Harnessing the Potential of Wood Chips

Wood chips, derived from various wood sources including logs, branches, and wood waste, serve as a potent biofuel with numerous advantages. Unlike pellets or sawdust, wood chips maintain their natural form, providing a high-energy-density fuel suitable for diverse applications, from heating residential homes to powering industrial processes.

Advanced Wood Chip Production Techniques

-

Optimal Wood Selection

Choosing the right wood species and quality is critical for efficient biofuel production. Hardwoods such as oak, maple and birch typically yield denser wood chips with higher energy content. Additionally, ensuring the wood is properly seasoned and free from contaminants enhances combustion efficiency and reduces emissions.

-

Precision Chipping

Investing in a high-quality woodchipper capable of producing uniform chip sizes, such as Jensen with its unique chipper chamber design and adjustable infeed roller speed, is essential for maximising energy output. Adjusting chipper settings to achieve the desired chip dimensions ensures consistent combustion and minimal ash residue. Operators can optimise chip quality and energy yield by fine-tuning chipper parameters based on wood moisture content and species characteristics, a feature available in all Jensen chippers.

-

Advanced Drying Techniques

While air drying remains a cost-effective method for reducing wood chip moisture content, advanced drying techniques such as kiln drying or solar drying offer faster and more controlled moisture removal. Implementing moisture sensors and automated drying systems enhances efficiency and reduces energy consumption during the drying process, resulting in higher-quality wood chips with superior combustion characteristics.

-

Storage and Preservation

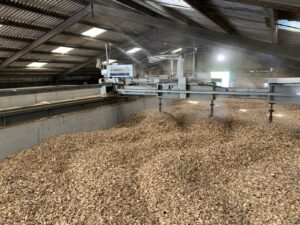

Proper storage is crucial for maintaining wood chip quality and preventing degradation over time. Utilising covered storage facilities with adequate ventilation minimises moisture absorption and fungal growth, preserving the energy potential of the wood chips. Implementing inventory management systems and rotational storage practices ensures a consistent supply of seasoned wood chips for biofuel production year-round.

Maximising the Benefits of Self-Produced Wood Chip Biofuel

-

Environmental Stewardship

By producing your own wood chips for biofuel, you’re actively contributing to carbon sequestration and reducing greenhouse gas emissions. Sustainable forestry practices and responsible wood sourcing further enhance the environmental benefits, promoting biodiversity and ecosystem health.

-

Energy Efficiency

Wood chips offer a renewable and efficient energy source with high energy density and low production costs compared to fossil fuels. Optimising wood chip production and combustion processes minimises energy waste and maximises energy output, resulting in a more sustainable and cost-effective energy solution.

-

Community Resilience

Embracing self-made wood chip biofuel production fosters local resilience and self-reliance by reducing dependence on centralised energy systems. Community-based initiatives and collaborative biomass supply chains strengthen local economies and empower individuals to take control of their energy destiny.

Producing your own wood chips for biofuel represents a tangible pathway towards sustainable energy independence and environmental stewardship. By leveraging advanced production techniques and optimising wood chip utilisation, individuals and communities can unlock the full potential of this renewable energy resource. So, let’s embark on this journey together, harnessing the power of self-made wood chip biofuel to create a greener, more resilient future for generations to come.

If you’d like to find out more about the Jensen range of Biomass Chippers, get in touch.

Or visit our website: www.jensenchippers.co.uk